- 2025-07-11

The Complete Guide to Neoprene Bags: Material, Design, and Market Trends

The Complete Guide to Neoprene Bags: Material, Design, and Market Trends

As a retailer exploring the neoprene bag market, you're entering a dynamic segment that combines functionality with fashion-forward design. Neoprene bags have evolved from their utilitarian origins in water sports to become coveted accessories in urban fashion and luxury markets. This comprehensive guide will provide you with essential knowledge about neoprene material properties, design considerations, manufacturing processes, and current market trends to help you make informed purchasing and merchandising decisions.

Understanding Neoprene Material

Composition and Properties

Neoprene, scientifically known as polychloroprene, is a synthetic rubber composed of chloroprene polymers. This remarkable material was first developed by DuPont scientists in 1930 and has since become indispensable across numerous industries. For bag manufacturers and retailers, understanding neoprene's unique characteristics is crucial for product selection and customer education.

Key material properties that make neoprene ideal for bags include:

Exceptional durability: Neoprene maintains its structural integrity through repeated use and abuse, with high resistance to tears, abrasions, and general wear. Bags made from neoprene can withstand daily use far longer than many traditional materials.

Water resistance: The closed-cell structure of neoprene foam makes it naturally water-resistant—a property that originated from its use in wetsuits. This means neoprene bags protect contents from rain, spills, and moisture without requiring additional treatments or coatings.

Thermal insulation: Neoprene provides excellent thermal regulation, keeping items at stable temperatures. This makes it particularly valuable for lunch bags, wine carriers, or any application where temperature control matters.

Shock absorption: The foam-like structure cushions contents against impacts, protecting delicate items like electronics or glass bottles during transport.

Flexibility and shape retention: Neoprene stretches comfortably while maintaining its original form, allowing for bags that conform to contents without sagging or losing structure over time.

Chemical resistance: Unlike many materials, neoprene resists degradation from oils, solvents, and other chemicals that might damage ordinary fabrics.

Material Variations and Specifications

Not all neoprene is created equal, and understanding the variations will help you select the right products for your customer base:

Foam thickness: Typically measured in millimeters, ranging from 1mm (ultra-lightweight) to 7mm (heavy-duty). Thinner neoprene (1-3mm) works well for fashion bags and tech sleeves, while thicker versions (4-7mm) suit more protective applications.

Fabric facing: Most neoprene used in bags has fabric laminated to one or both sides. Common facing materials include:

Nylon/Lycra blends (for stretch and durability)

Polyester (for printability and colorfastness)

Specialty coatings (like PU for enhanced water resistance)

Density variations:

Low-density (softer, more flexible)

Medium-density (balanced performance)

High-density (more rigid, better structure)

Specialty neoprene types:

CR (Chloroprene Rubber) - The original formula with excellent all-around performance

SBR (Styrene-Butadiene Rubber) - More economical but with reduced chemical resistance

EPDM (Ethylene Propylene Diene Monomer) - Superior weather resistance

Environmental Considerations

Modern consumers increasingly demand sustainable options, and neoprene presents both challenges and opportunities in this regard:

Traditional neoprene is petroleum-based and not biodegradable, raising environmental concerns.

Eco-friendly alternatives now include:

Limestone-based neoprene: Uses calcium carbonate from limestone instead of petroleum, reducing carbon footprint by up to 30% 2

Recycled neoprene: Repurposed from manufacturing waste or post-consumer products

Plant-based alternatives: Emerging materials using natural rubber blends

Recycling challenges: While technically recyclable, neoprene's composite nature (often bonded with other materials) makes practical recycling difficult. Some brands now design for disassembly to facilitate recycling 4.

As a retailer, offering neoprene bags with clear sustainability credentials can be a significant differentiator in today's market.

Neoprene Bag Design Fundamentals

Structural Design Elements

Neoprene's unique properties enable innovative bag designs that combine functionality with aesthetic appeal. Understanding these design elements will help you evaluate product quality and match bags to specific use cases:

Seam construction:

Serged seams: Common in sportier designs, where threads wrap around fabric edges

Welded seams: Heat-sealed for waterproof integrity, increasingly popular in high-end designs 4

Laminated seams: Using adhesive tapes for a clean, minimalist look

Edge finishing:

Raw-cut edges for a sporty, casual aesthetic

Bound edges with fabric tape for a polished finish

Laser-cut precision edges in premium designs

Closure systems:

Zippers (water-resistant or standard)

Magnetic snaps

Drawstring tops

Roll-top designs for expandability

Handle and strap options:

Integrated neoprene straps (comfortable and stretchy)

Detachable webbing straps (for adjustability)

Leather or chain straps in fashion-forward designs

Ergonomic padded handles for comfort

Functional Design Features

Beyond basic structure, well-designed neoprene bags incorporate thoughtful features that enhance usability:

Organization systems:

Interior pockets (zippered, slip, or elasticized)

Key clips or leashes

Dedicated laptop/tablet compartments

Exterior quick-access pockets

Protective elements:

Padding in high-impact areas

Reinforced bases

Scratch-resistant linings for electronics

Carry options:

Crossbody configurations

Backpack conversions

Tote handles with drop lengths optimized for shoulder carry

Modular attachment points for accessories

Aesthetic Design Considerations

Neoprene's versatility allows for diverse aesthetic expressions across market segments:

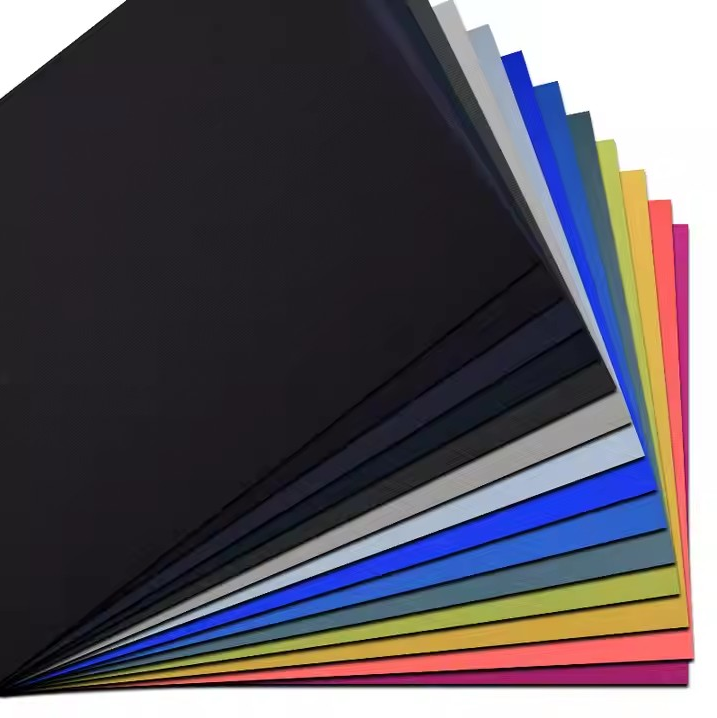

Color treatments:

Solid colors (from vibrant brights to sophisticated neutrals)

Two-tone combinations

Ombré or gradient effects

Printed patterns (camouflage, florals, geometrics) 1

Surface textures:

Smooth matte finishes

Waffle or honeycomb textures

Embossed or debossed logos/patterns

Fabric-laminated looks (mimicking linen, denim, etc.)

Branding techniques:

Silkscreened graphics

Embroidered logos

Patches or appliqués

Laser-etched detailing

Hybrid constructions:

Neoprene paired with leather accents

Mixed-material panels (mesh, canvas, etc.)

Transparent PVC overlays

Understanding these design elements will help you curate a neoprene bag assortment that meets diverse customer needs while maintaining strong brand aesthetics.

Neoprene Bag Typology and Market Applications

Product Categories

The neoprene bag market encompasses several distinct product categories, each with specific design requirements and customer expectations:

Laptop/Tablet Sleeves:

Slim-profile protective cases

Standard sizes matching common device dimensions

Often feature microfiber linings and precise fits

May include accessory pockets for chargers, etc.

Everyday Carry Bags:

Crossbody/shoulder bags (typically 5-10L capacity)

Compact designs for urban commuting

Multiple organization compartments

Water-resistant zippers

Beach & Pool Bags:

Larger capacities (15-30L)

Drainage grommets for wet items

Sand-resistant materials

Bright, vacation-appropriate colors

Lunch & Thermal Bags:

Insulated compartments

Leak-proof linings

Easy-to-clean surfaces

Compact folding designs

Fashion Totes:

Oversized constructions

Structural rigidity despite flexible material

High-end finishes and details

Often hybrid designs with leather or metal elements

Specialty Bags:

Wine bottle carriers

Camera equipment bags

Yoga/gym bags

Diaper bags

Market Segment Considerations

Different consumer segments prioritize distinct features in neoprene bags:

Professional/Workplace:

Sophisticated aesthetics

Device protection

Organization features

Neutral color palettes

Student/Youth:

Affordable price points

Bold colors/patterns

Durable constructions

Hands-free carrying options

Fashion-Conscious:

Designer collaborations

Unique textures/colors

Brand visibility

Seasonal trends

Outdoor/Adventure:

Rugged durability

Maximum water resistance

Attachment points for gear

High-visibility elements

Eco-Conscious:

Sustainable material claims

Recyclable constructions

Natural colorways

Minimalist designs

Understanding these segment-specific needs will help you tailor your product selection and marketing messaging effectively.

Manufacturing and Quality Considerations

Production Processes

Neoprene bag manufacturing involves specialized techniques that differ from traditional bag production:

Material Preparation:

Neoprene sheets are typically delivered in rolls

Fabric lamination occurs before cutting in many cases

Precision laser cutting minimizes material waste

Assembly Methods:

Sewing requires specialized needles to penetrate dense material

Seam sealing often follows stitching for water resistance

Welding techniques create seamless joins in premium products 4

Finishing Processes:

Edge binding or taping

Hardware attachment (zippers, snaps, etc.)

Quality control for consistent thickness and density

Quality Indicators

When evaluating neoprene bag suppliers, consider these markers of quality:

Material Integrity:

Consistent thickness throughout

Even lamination without bubbles or peeling

Uniform density without weak spots

Construction Quality:

Reinforced stress points (corners, strap attachments)

Straight, even stitching

Properly aligned patterns/graphics

Smooth zipper operation

Performance Testing:

Water resistance validation

Seam strength tests

Colorfastness ratings

Abrasion resistance

Certifications:

<ul style="margin-top: 4px; padding-l

Hits: 【Print】

Send Email

Send Email